Bending and formation of metal sheet is achieved on bending machine in the following steps that putting the to-be-formed work-pieces on the bending machine, lifting the brake shoe up with a lifting lever, pushing the work-piece to the appropriate position, and then lowering the brake shoes on the to-be-formed work-piece to achieve metal bending by applied force of bending lever on the bending machine. The minimum bending radius is the function of extension and thickness of formed metal. For aluminum sheet, the bending radius is larger than thickness. In bending, the bending angle of metal is commonly larger than the required because it has certain springback.

Product advantages

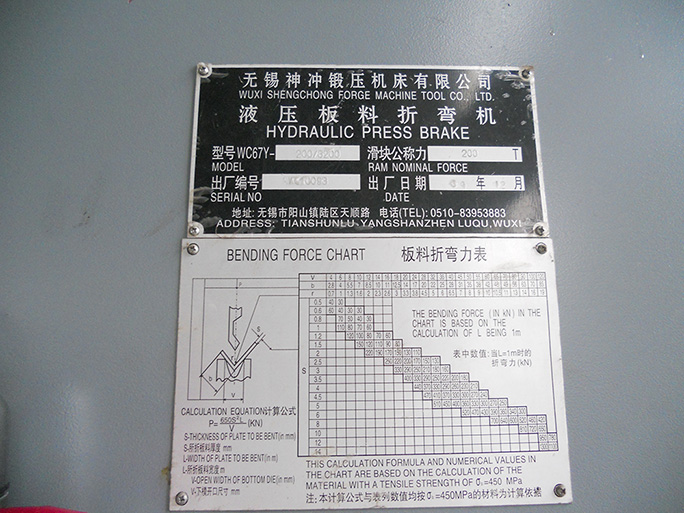

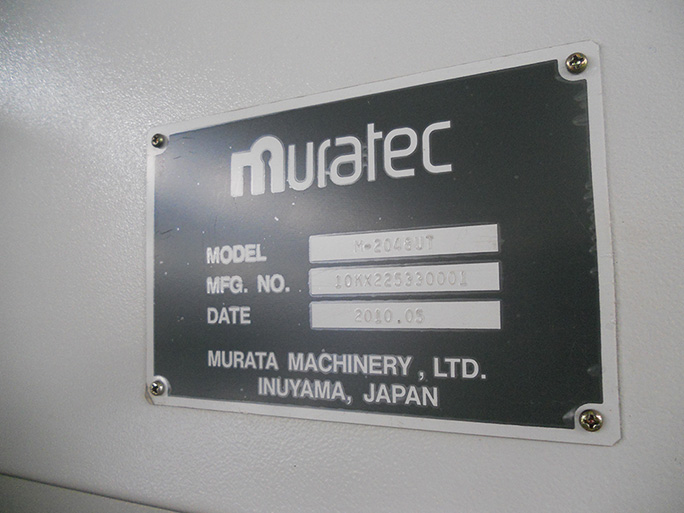

We have two CNC bending machine from Bystronic, five ACL CNC electrohydraulic synchronous CNC bending machines and one common hydraulic plate bending machine.

It has the maximum bending width of 4,100mm, and the maximum post-positioning size of 1200mm, maximum tonnage of 320t, and processing precision tolerance of ±0.004 mm.

We can make full use of performance and advantages of bending machine to make satisfied and fine products for customers.