Injection molding processing is to add plastic particles into a drum by a feed hopper, heat it to a certain temperature and hold for some time, uniformly plastify it under certain stirring strength and speed, inject into the moulds under pressure, thrust and speed to form the shapes, and then cold it under the effect of pressure.

Product advantages

We mainly employ the injection molding to produce textile machinery parts which are mostly made from engineering plastic, as engineering plastic, with excellent hardness, toughness, wear resistance and anticorrosion, can substitute for steel, iron and other raw materials in a larger range.

We have set up mould research & development team, all moulds developed are used in production of plastic products and can meet production demands after pilot test to produce one-time forming plastic products as customers required, contributing to saved labor, saved raw material and high product precision. Meanwhile, products made by our moulds incorporating with injection molding machine are controlled within ±0.02 mm in tolerance.

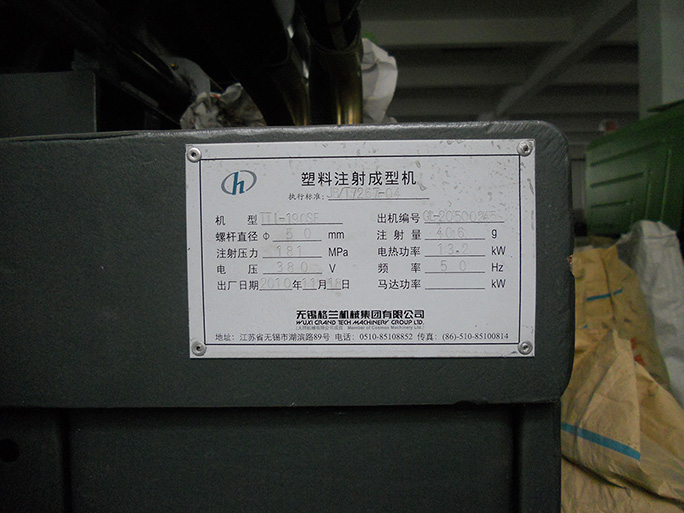

TTI series injection molding machine is an energy-saving one equipped with CML servo system, is safe and stable as reaching Grade I safety level, and has low energy consumption and high yield.