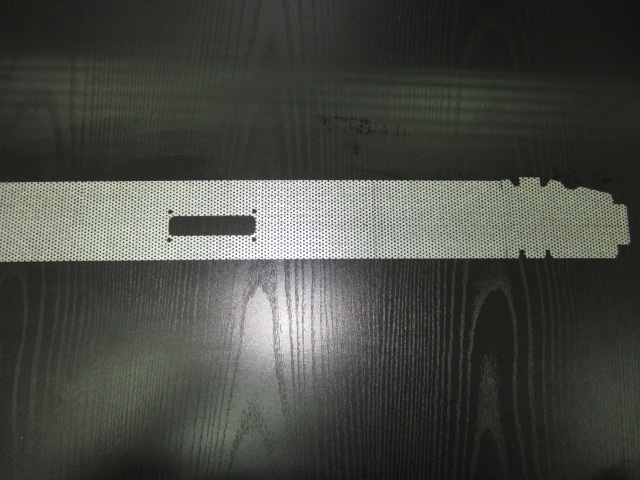

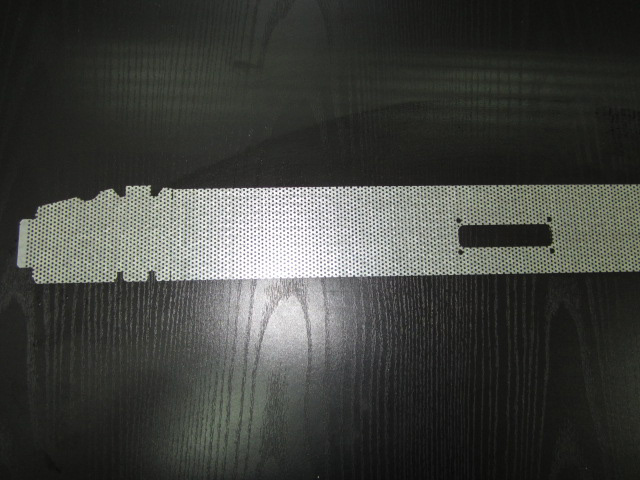

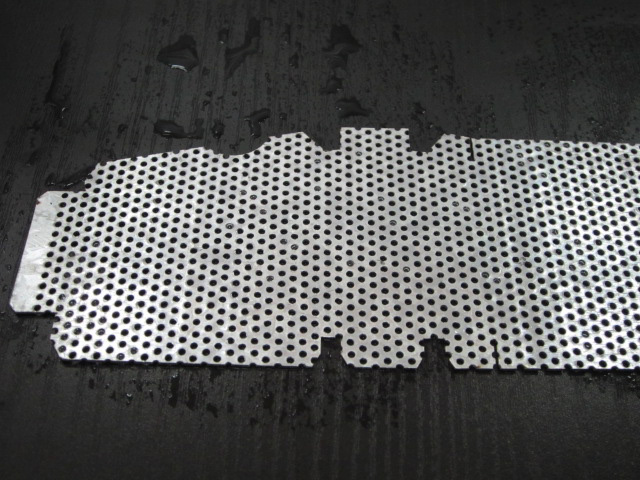

Laser cutting process utilizes energy emitted by laser beams irradiating on the surface of steel plate to smelt and evaporate stainless steel, its laser beam commonly is CO2 laser beam. Its power is lower than that of many household electric heaters, and however, the laser beam gathers on a small area through the lens and reflector, the high concentration of energy contributes to rapidly partial heating and evaporation of stainless steel. Otherwise, because the energy is highly concentrated, there are few of heat transferring to the other part of steel, leading to small or no deformation. It can accurately cut complicated blank, without needing further treatment.

Product advantages

We own two laser cutting machines imported from Bystronic. The maximum thickness of sheet metal is 25.0mm, and the tolerance of processing precision is ±0.1 mm.

Laser technology is widely used in the machining field. The laser processing technology utilizes the interaction of laser beam and material for cutting, welding, surface treatment, punching and micromachining to materials, is used as a light source to distinguish objects, and has become one key technology in industrial automatic production. Its valuable characteristics of good coherence, monochromaticity and direction and high brightness make it superior in the machining field.

Our laser operators who have first-rate operation technology, rich field experience and sophisticated programming technology can help customers save raw materials and reduce burrs.

Range of Conventional Material Machining:

| Model | Material: Common steel | Material: Stainless steel | Material: Aluminum |

| ByJin 3015 | 1.0~20.0 mm | 1.0~12.0 mm | 1.0~8.0 mm |

| ByStar 4020 | 1.0~25.0 mm | 1.0~18.0 mm | 1.0~12.0 mm |